1.Mechanics Thiab Fatigue Fracture:

● Metal conventional mechanical performance testing (-196 ℃ --- 1000 ℃, tensile, compression, torsion, impact, hardness, elastic modulus);

● Hlau qaug zog thiab tawg kev ua tau zoo (-196 ℃ --- 1000 ℃, axial siab / qis voj voog qaug zog, rotating dabtsi yog khoov qaug zog, tawg qhov kev loj hlob, tawg toughness, thiab lwm yam);

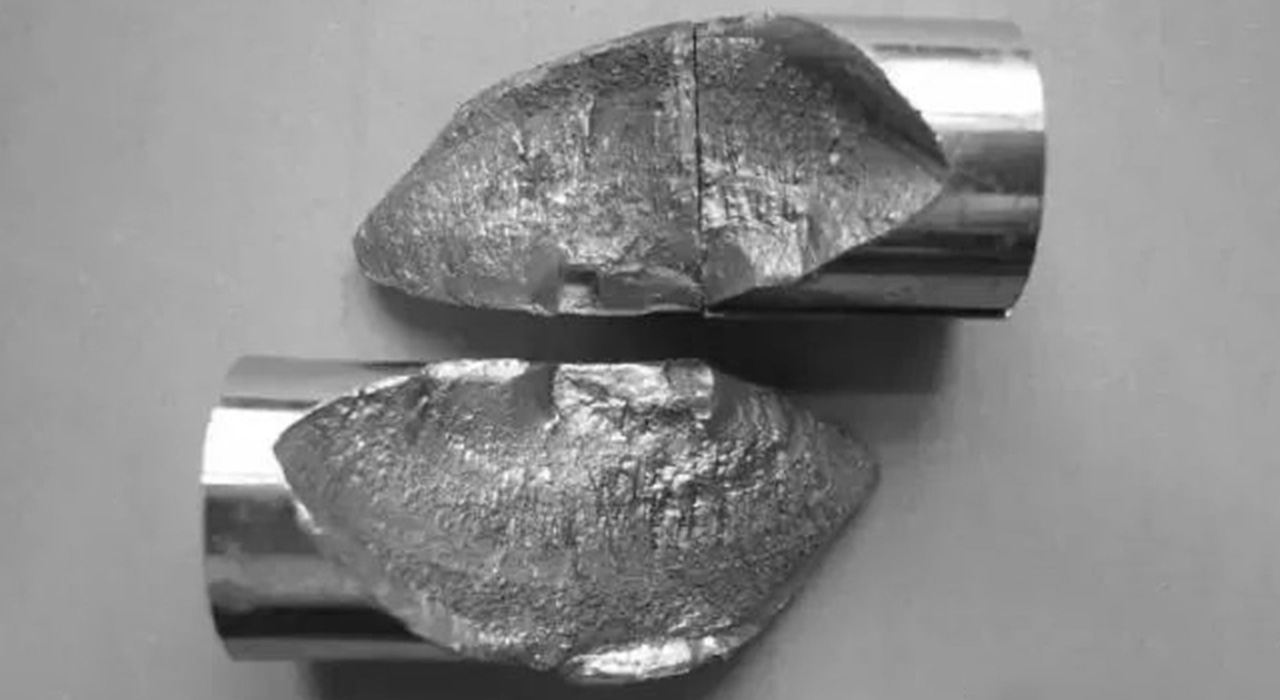

●CTOD xeem ntawm nkoj thiab dej hiav txwv hlau;ultra-low kub, loj tuab phaj tawg taub hau

● Hlau durability thiab siab kub creep kev ua tau zoo kuaj;

● Kev ua tau zoo ntawm cov khoom tsis yog hlau thiab cov khoom sib xyaw;

2. Rail Transit:

Nyob rau hauv kev teb rau cov kev xav tau ntawm txoj kev tsheb ciav hlau kev lag luam rau lub teeb yuag, lub zog siab, kev sib cais ntawm kev co thiab kev vibration txo, kev nyab xeeb thiab kev tiv thaiv ib puag ncig, kev soj ntsuam kev ntseeg siab ntawm cov tsheb ciav hlau thiab cov khoom siv tsheb ciav hlau tau ua tiav, thiab cov txheej txheem kev taw qhia thiab kev txhawb nqa yog muab. rau kev xaiv cov khoom siv thiab kev siv engineering.Cov khoom siv tseem ceeb yog:

● Kev ntsuas kev ua tau zoo ntawm cov hlau nplaum muaj zog thiab cov profiles rau cov tsheb ciav hlau;

● Kev ntsuam xyuas cov khoom ntawm cov khoom tseem ceeb xws li bogies, gearboxes thiab log ntawm rail tsheb lub cev;

● Corrosion kuj thiab qaug zog kuaj ntawm railcar lub cev cable brackets thiab lwm yam khoom;

● Dynamic thiab static rigidity thiab corrosion kuj kuaj ntawm kev co damping fastener system;

● Durability xeem ntawm kev co cais cov ntaub qhwv thiab elastic pads ntawm taug kev txaj;

● Rub-tawm lub zog thiab kev qaug zog ntawm cov fasteners rau kev tsim kho;

● Kev qaug zog kev ua tau zoo ntawm kev taug qab cov ntaub thaiv npog qhov ntu ntu.

● Kev sim qaug zog ntawm txoj kev tsheb ciav hlau thiab cov khoom siv pw tsaug zog;

● Kev soj ntsuam kev nyab xeeb ntawm cov khoom siv thauj khoom ntawm kev tsheb ciav hlau;

3. Hluav taws xob:

Raws li qhov cuam tshuam ntawm petrochemical thiab thee chemical media ntawm cov khoom siv corrosion, kev tshawb nrhiav hauv online tuaj yeem ua tiav los muab cov kev daws teeb meem zoo rau kev ua haujlwm nyab xeeb ntawm cov khoom siv.Cov khoom siv tseem ceeb yog:

● Kev tshawb nrhiav Corrosion (kev ntsuas tuab, ntsuas ntsuas, ntsuas qhov tsis xws luag, txheeb xyuas cov khoom siv, thiab lwm yam);

● Txheej txheem los tiv thaiv corrosion thiab corrosion xyuas rectification tswv yim;

● Kev soj ntsuam tsis ua tiav thiab kev txheeb xyuas kev lav phib xaub;

● Kev ntsuas kev nyab xeeb thiab kev ntsuas lub neej ntawm cov khoom siv siab.

4. Nkoj Thiab Dej Hiav Txwv Engineering:

Raws li "Ship Material Verification Test Center" tau tso cai los ntawm CCS, nws tuaj yeem ua cov khoom siv thiab cov khoom siv ntsuas kev ua tau zoo thiab kev kuaj xyuas rau kev tsim cov nkoj thiab sab nrauv cua fais fab, offshore roj thiab roj kev loj hlob, offshore drilling platforms thiab lwm yam khoom siv.Cov khoom siv tseem ceeb yog:

● Kev soj ntsuam cov khoom siv nkoj thiab kev txheeb xyuas ntawm lub nkoj;

● Kev ntsuas kev ua tau zoo ntawm cov khoom siv nkoj tshwj xeeb (cov neeg nqa roj av, CNG nkoj, LNG nkoj);

● Nkoj phaj thickness ntsuas thiab ntsuas qhov tsis xws luag;

● Kev tshuaj xyuas lub zog (yield thiab instability) thiab kev qaug zog ntawm cov qauv ntawm lub cev;

● Kev txheeb xyuas qhov xwm txheej ntawm cov khoom siv hauv nkoj (fais fab system, mooring system, piping system);

● Kev ntsuam xyuas kev ntseeg tau ntawm cov qauv kev lag luam sab nrauv;

● Txheej kev ntsuas kev ua tau zoo;

● Kev tshuaj xyuas, kev soj ntsuam tus qauv thiab kev soj ntsuam ntawm cov khoom phom sij ntawm cov nkoj hla hiav txwv.

5. Corrosion Performance Test:

Nws yog tsuas yog siv los kuaj xyuas cov khoom siv tshuaj lom neeg lossis lub cev (lossis kho tshuab) cov txheej txheem kev puas tsuaj los ntawm kev sib cuam tshuam ntawm cov hlau thiab cov ntaub ntawv tsis yog hlau nrog ib puag ncig, txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhuam nws nws nws thiab ib puag ncig, thiab nkag siab txog corrosion mechanism.Zoo tswj cov txheej txheem corrosion.

● Stainless hlau intergranular corrosion, pitting corrosion thiab crevice corrosion

● Exfoliation corrosion thiab intergranular corrosion ntawm aluminium alloy

● Sab hauv kev ntsuas corrosion nrawm uas simulates marine ib puag ncig (tag nrho immersion, inter-immersion, ntsev tsuag, galvanic corrosion, ceev immersion corrosion, thiab lwm yam);

● Electrochemical kev ua tau zoo ntawm cov khoom siv lossis cov khoom siv;

● Electrochemical kev ua tau zoo ntawm sacrificial anode, auxiliary anode thiab siv electrode;

● Sulfide kev nyuaj siab corrosion thiab corrosion qaug zog;

● Kev ntsuas kev ua tau zoo thiab kev sim tshuab ntawm cov hlau thiab cov txheej txheem sib xyaw;

● Kev ntsuam xyuas kev ua tau zoo hauv kev simulated hauv hiav txwv tob;

● Kev kuaj xyuas microbiological corrosion;

● Kev tshawb fawb txog kev loj hlob ntawm tus cwj pwm hauv electrochemical ib puag ncig;

● Siab, nruab nrab thiab qis ceev dynamic rotor scour simulation xeem

● Pipeline scouring simulation xeem

● Tidal range/interval immersion simulation test

● Hiav txwv dej tsuag + atmospheric exposure accelerated test

6. Aerospace:

Kev sib xyaw ua ke ntawm cov khoom siv muaj zog aluminium alloys, titanium alloys, thiab cov khoom sib xyaw ua ke hauv cov khoom tseem ceeb xws li aero engines, cabin aluminium alloy daim hlau thiab cov khoom siv, cov khoom siv dav hlau, aviation fasteners, tsaws iav, propellers, thiab lwm yam., ua kom tiav thiab ua haujlwm Kev ntsuas kev ua tau zoo thiab kev ntsuas kev nyab xeeb.Cov khoom siv tseem ceeb yog:

● Cov khoom siv lub cev thiab tshuaj lom neeg kev xeem;

● Kev kuaj lub cev thiab tshuaj lom neeg nyob rau hauv ib puag ncig kev pabcuam tshwj xeeb (ultra-low temperature, ultra-high temperature, high-speed loading, etc.);

● Kev sim qaug zog thiab ua haujlwm ntev;

● Kev soj ntsuam tsis ua haujlwm thiab kev ntsuas lub neej.

7. Automotive Engineering:

Nws muaj peev xwm ua tiav kev soj ntsuam kev ntseeg tau thiab kev saib xyuas zoo ntawm cov tsheb hlau, cov khoom tsis yog hlau thiab lawv qhov chaw.

Cov khoom siv tseem ceeb yog:

● Kev kuaj cov khoom siv hlau (kev soj ntsuam tsis ua haujlwm, kev kuaj xyuas cov cuab yeej cuab tam, kev tshuaj xyuas microscopic, kev tshuaj ntsuam xyuas metallographic, kev tshuaj ntsuam txheej, kev kuaj corrosion, kev soj ntsuam pob txha, kev kuaj vuam, kev kuaj tsis muaj kev puas tsuaj, thiab lwm yam);

● Corrosion test thiab qaug zog.